- Home

- About Us

-

Products

- Cut & Bent Rebar

- Reinforcing Fabric

- Prefab Solutions

- Couplers

- Construction Accessories

- Concrete, Plastic and Wire Reinforcement Spacers

- Construction Chemicals, Grouts, Mortars and Resins

- Gabion Baskets

- Groundwork and Slab Accessories

- Rebar Couplers

- Permanent Formwork,Column Formers and Formwork Accessories

- Site Safety and Test Equipment

- Waterproofing and Gas Barriers

- Spread Anchor System

- Lifting & Fixing Systems

- Precast Accessories

- Brickwork Products

- Technical Solutions

- Sustainability

- Technical Services

- Resources

- Contact Us

7 Steel Service supply advanced mechanical rebar splicing systems to suit a wide range of applications and in a spread of diameters from 10mm to 50mm.

Advanced mechanical rebar splicing systems come with a wealth of support and real world experience in problem solving related to fixing rebar along with the value they bring to modern methods of construction (MMC)

nVent LENTON taper-threaded rebar splicing system is a well recognised global brand

Why use nVent Lenton Coupler System

Reduced Installation Time & Labour

Their taper-threaded couplers require only about 4–5 turns to fully engage / splice the bars, whereas many parallel-threaded or other systems need 10–12 turns. This speeds up installation significantly, especially for large numbers of couplers.

The self-aligning taper thread helps prevent cross-threading, which reduces mistakes and rework.

High Quality & Reliability

- Their taper thread design (conical taper) gives more uniform load distribution across threads and better engagement than many parallel-threaded designs. This leads to better performance, less slip under load, etc.

- They have strong certifications and approvals (e.g. CARES, BS standards etc.) which helps ensure quality and acceptance.

Versatility / Flexibility

Wide range of coupler types to suit different situations:

- Standard couplers (for when one or both bars can be rotated).

- Position/transition couplers (for cases when bars cannot be rotated or are restricted axially).

- Weldable couplers for joining rebar to structural steel or plates.

- Coated, stainless steel, different finishes for corrosion resistance.

Slim Profile / Small Size

- The couplers are relatively slender, so they help maintain concrete cover and allow tighter bar spacing. That can be essential in congested rebar areas.

Good Load Transfer & Structural Integrity

- They provide continuity of the reinforcing steel; the splice behaves close to a continuous bar in many cases.

- In tensile, compression, and stress-reversal (e.g. seismic) scenarios, the performance is good.

Corrosion Resistance Options

- Stainless steel or coated coupler options help where the environment is corrosive (bridges, marine, de-icing salts).

Reduced Inspection & Testing Costs (versus alternative methods)

- In some cases, using couplers reduces the need for certain tests or inspections needed when welding or lap splicing, which saves cost.

Improved Safety and Reduced Risk on Site

- Less manual handling / fewer labour hours means lower exposure to accidents.

- By reducing cross-threading and misalignment risk, fewer reworks and site errors.

Suitability for Prefabrication / Offsite Work

- Couplers allow prefabricated cage assemblies, precast elements where part of the coupler is fitted in the factory and the rest on site, giving better quality control.

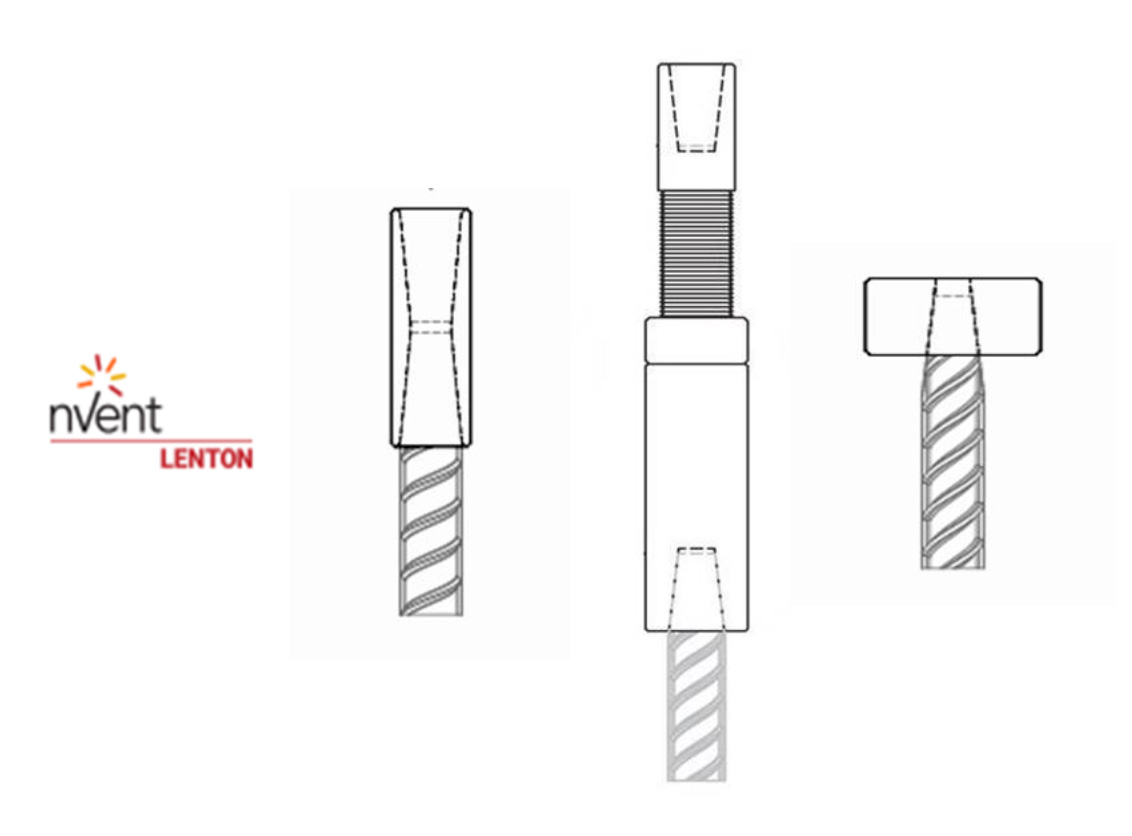

nVent Lenton offers 3 different levels of coupler system as detailed below;

- LENTON” by itself often refers to the baseline / original family of taper-threaded rebar coupler systems from nVent (originally ERICO / Lenton).

- “LENTON Plus” is a variant or improved version within the LENTON line, intended for certain bar size ranges with improved fracture behavior.

- “LENTON Ultimate” is their higher-performance, more advanced coupler system using friction forging for attaching the coupler to the rebar, offering greater tolerances and performance.

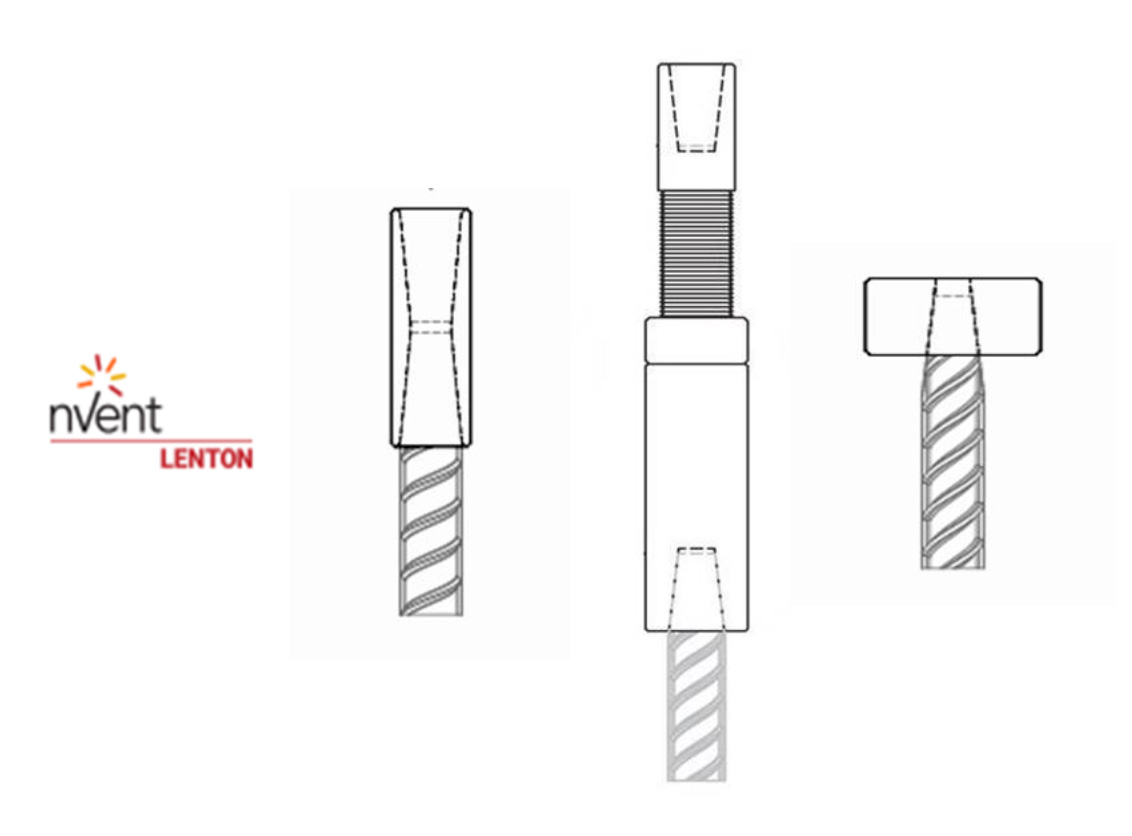

nVent Lenton also offer a remedial coupler solution – called nVent Lenton Connect

nVent LENTON Connect is a shear bolt coupler for the connection of reinforcement bars from 12mm to 32mm. Requires no special bar end preparation.

It is ideal for new construction, repair or retrofit applications.